Machine description

Machine description Specification

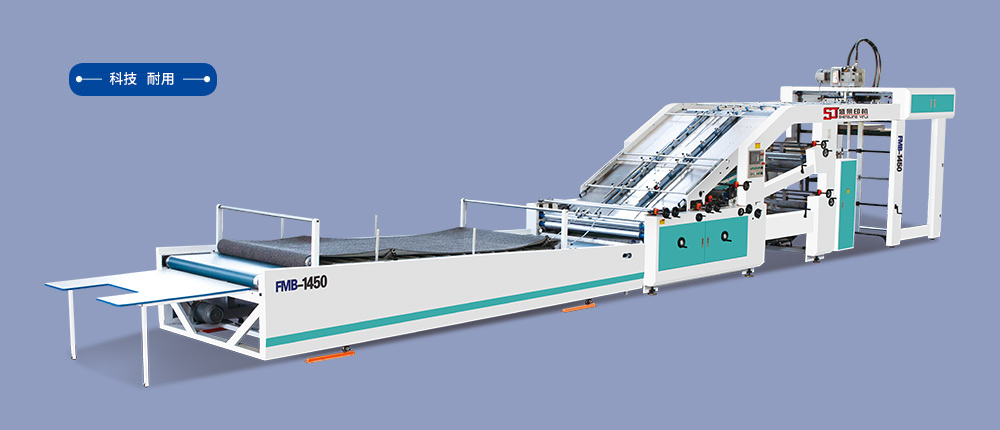

Specification| Model | FMB-1450S | FMB-1600S | FMB-1450L | FMB-1600L |

| Max. Paper Size(mm) | 1450×1400 | 1600×1400 | 1450×1400 | 1600×1400 |

| Min. Paper Size(mm) | 500×500 | 500×500 | 500×500 | 500×500 |

| Thickness of Face Paper(g/m2) | 150-500 | 180-500 | 180-500 | 180-500 |

| Thickness of Bottom Paper(mm) | A/B/C/D/E Corrugated Paper | A/B/C/D/E Corrugated Paper | A/B/C/D/E Corrugated Paper | A/B/C/D/E Corrugated Paper |

| Laminating Precision(mm) | ±1.5 | ±1.5 | ±1.5 | ±1.5 |

| Max. Speed(m/min) | 7000 | 7000 | 5000 | 5000 |

| Total Power(kw) | 24 | 26 | 24 | 26 |

| Total Weight(kg) | 7300 | 7500 | 7500 | 7500 |

| Power Supply | 380V 3P 5W 50HZ | 380V 3P 5W 50HZ | 380V 3P 5W 50HZ | 380V 3P 5W 50HZ |

| Dimension (mm) | 16500×2300×2950 | 16500×2450×2950 | 16500×2300×2950 | 16500×2450×2950 |

Other equipment specifications can be customized

Details features

Details features-

Face Paper Feeding Unit

Face Paper Feeding UnitAdopting a four-suction and five-delivery heavy-duty Feeder head, combined with a high-power vacuum pump, suitable for efficient and precise output of thick and thin paper.

-

Gluing Unit

Gluing UnitThe gluing roller made with mirror technology has a more uniform gluing process, saves glue amount, and effectively reduces usage costs.

-

Bottom Paper Feeding Unit

Bottom Paper Feeding UnitThe upper and lower bottom papers conveying adopt combination of servo motor and high-strength vacuum suction to ensure feeding the corrugated paper accurately and quickly.

-

Face Paper Front Lay Unit

Face Paper Front Lay UnitThe face paper adopts belt pressurized conveying, and the positioning adopts an elastic front lay, which can achieve automatic positioning regardless of the size of the paper.

-

Paper Aligning and Conveyor Unit

Paper Aligning and Conveyor UnitThe combination of synchronous conveyor belt and dynamic side lay ensures automatic positioning of paper during travel, and the positioning accuracy can be adjusted without stopping the machine.

-

Paper Receiving and Conveyor Unit

Paper Receiving and Conveyor UnitThe combination of aluminum alloy plate and polyurethane rubber wheel ensures paper feeding without slipping, easier adjustment and more efficient conveying efficiency.

冀公网安备13022902000403

冀公网安备13022902000403